WHAT WE DO

From engineering and planning to construction of houses, shopping malls and highways and metro stations for big cities all over the world.

Focused on city construction, big box, commercial buildings and also industrial. More than 70 years experience into building construction with the best expertise.

Being into the construction field you will have to look for more efficient ways to finish projects, and also keep an eye open for the environment. Our company focus is to help get green energy.

Half century experience in infrastructure projects, through the fund of building smarter cities in United States we’ve been able to create amazing landmarks and projects.

Both these stiffen the yacht and allow more sail to be carried in stronger winds. Depending on the type of race, such a yacht may have a crew of 15 or more.

Innovation is at the core of what we do. On any given project in any location, our engineers encounter some of the most complex and challenging problems.

Implementing all forms of insulation for buildings, new or insulation retrofit at any size. Our green insulation materials are focused more on: spray foam, fiberglass, reflective, loose fill or thermal insulation.

Construction Contractors has a proven track record of successfully completing many large scale retail projects. We do whatever it takes to satisfy our clients. Our long-term relationships with numerous national clients prove our successful communication abilities and high-quality services. We exceed our clients’ expectations whether we are retrofitting an existing structure or building an entirely new store.

Being into the construction field you will have to look for more efficient ways to finish projects, and also keep an eye open for the environment. Our company focus is to help get green energy.

Our renewable energy service team offers quality civil site construction solutions to your wind energy, solar energy and energy storage infrastructure needs. Our expertise and civil site construction approach to large utility scale projects will help you manage project costs, expedite your construction schedule and optimize your power project to ensure that your project delivery methods and processes are executed as planned. Call us today and together we will ensure your clients are satisfied!

We design, install, and maintain solar panels on both industrial and commercial properties. Providing safe, reliable, and sustainable energy to empower communities.

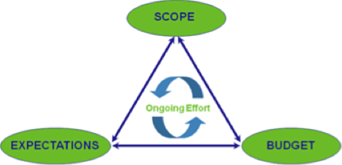

By focusing on safety and efficiency in all that we do, we can provide on-time results that exceed the expectations of our clients. As a self-performing construction builder, our company has the expertise required to directly control the project’s quality, budget, schedule, and safety.

We understand that time and quality are of utmost importance on heavy civil construction projects and related tasks. At our heavy civil infrastructure company, we recognize this importance, not just the owners, but to the organization as a whole. We take the time to establish a project schedule, and we use this plan to track and monitor the progress of our work. With us on your side for your municipal construction and other jobs, you will have your project completed on time and on budget.

Whether your project needs include just paving and sidewalks, or a full, turn-key experience including wall installation, erosion control and utilities installation, you can be confident that our team of professionals will do their very best to make sure your project is beautifully completed according to plan, on budget, and on time.

When rocks erode out of the Rocky Mountains and are carried downstream by streams and rivers, they break apart making sand and gravel. The sand and gravel settles out of the water and form the river bed. As the river channel moves across the landscape, the sand and gravel (aggregate) deposits are left behind. That is where we come in, and get the materials to your project.

Our focus is on meeting your individual requirements for the widest variety of applications. We identify and acquire appropriate deposits, use resources optimally and produce high-quality products. Each step of the process is assessed, from site identification, through blasting, mining, processing and delivery.

We constantly work to discover new uses for our products and optimize practices. By anticipating future applications we will continue to provide you with innovative and value-adding solutions.

We deal with the designing, planning, construction and management of infrastructures such as roads, tunnels, bridges, airports, railroads, facilities, plants, manufacturing facilities, buildings, dams, utilities and other projects.

All construction companies incur costs to remain operational. However, to stay competitive, new ways of doing business have to be adopted, implemented, and promoted.

Cost reduction cannot be resolved with a set of tools or ideas, but with a holistic approach that addresses shortcomings in construction business practices. It involves considering each activity as part of a business system and not merely an isolated part that needs to be addressed.

In doing this, steps are taken from early in the design phase to other far-reaching areas that affect the day-to-day operation of a construction business, project planning, execution, project delivery, and operation.

There are several factors to consider when specifying insulation for commercial and industrial applications. Two primary considerations are choosing the right product for your needs and determining the proper insulation thickness for optimal product performance and efficiency.

When choosing an insulation product, it’s important to understand that there’s no such thing as a “superior insulator.” According to the Building Sciences Corporation, all types of insulation perform equally well when properly installed and air sealed.1 Still, there are several factors to consider when comparing insulation types.

Maximize your R-value per dollar. Given the fact that all insulators are equal when properly installed and air sealed, the goal is to maximize the R-value you achieve for the dollar you spend. You may see a product that claims to be a “superior insulator” because it achieves a higher R-value per inch of insulation, but all products with the same R-value can insulate equally well. So aim to get the most R-value for your budget in your chosen insulation material.

Aim for minimal air filtration. According to the National Association of Home Builders (NAHB) Research Center and several other independent tests, when fiber glass insulation and mineral wool insulation are paired with standard air sealing practices (including taped house wrap or caulk), air infiltration is effectively reduced to near zero2,3,4,5

Consider product settling. Fiber glass and mineral wool batts do not settle—and loose-fill fiber glass and mineral wool only settle a negligible amount—so their thermal performance is maintained for the life of the building.6

Research UV stability. Fiber glass insulation and mineral wool insulation are UV stable, meaning they do not experience shrinkage or thermal performance loss with exposure to ultraviolet rays. Spray foam is susceptible to UV exposure, which may compromise its performance.7

Insulation can help you create acoustically sound environments, where building occupants can take advantage of a relaxing, peaceful space—or turn up the volume without disturbing others. Fiber glass and mineral wool insulation give your buildings an edge by achieving a high level of sound control between interior rooms, between ceilings and floors, and from outside sources. Installing fiber glass or mineral wool batts is also an easy way to apply acoustical control to interior walls without changing build practices.

Fiber glass insulation and mineral wool insulation – Achieve a Sound Transmission Class (STC) of 438 as part of a complete exterior 2″x4″ wood framed wall system9

Spray foam insulation – Achieves an STC of 37-398

Sound insulation and sound absorption

Fiber glass insulation and mineral wool insulation – Noise Reduction Coefficient (NRC) of up to 1.0010 (with NRC, higher is better)

Spray foam insulation and cellulose insulation – Achieve an NRC of .7510

Fiber glass insulation and mineral wool insulation – are naturally non-combustible11

Spray foam insulation – Spray foam insulation will ignite at 700°F.12

Cellulose insulation – requires manufacturers to apply approximately 20%, by weight, of fire retardants to reduce flammability.13 This adds fire-resistance, but the resulting material is not non-combustible or smolder-resistant. The Consumer Products Safety Commission requires cellulose manufacturers to warn customers that products present a fire hazard.14

Fiber Glass insulation and Mineral Wool insulation – The International Agency for Research on Cancer (IARC), the US National Toxicology Program (NTP) and the California Office of Environmental Health Hazard and Assessment have all stated that fiber glass and mineral wool thermal and acoustic insulations are not considered classifiable as carcinogens.

Spray Foam Insulation – contains isocyanates that may cause asthma and “sensitization.” There is no recognized safe level of exposure to isocyanates for sensitized individuals; isocyanates have been reported to be the leading attributable chemical cause of work-related asthma; both dermal and respiratory exposures can trigger adverse health responses.15 Evacuation of all other trades from the entire structure is required during installation.

Fiber glass insulation and mineral wool insulation:

Require no drying or curing time during installation – and therefore do not introduce moisture into the cavity (unlike cellulose and spray foam, which are typically applied wet)

Absorb less than 1% of its weight in moisture – unlike cellulose, which absorbs 5–20% of its weight16

Come in unfaced products that are inorganic – meaning mold cannot feed on them (unlike cellulose, which is organic and a possible food source for mold)

Are available in batts with specialty facings and advanced smart vapor retarders – to help moisture escape the cavity

Fiber glass insulation and mineral wool insulation:

Contain recycled materials – Fiber glass contains 40-60% recycled content, depending on the manufacturer. Mineral wool insulation products vary by makeup. Rock wool insulation contains an average of 10-15% recycled blast furnace slag. Slag wool insulation contains 70-75% recycled blast furnace slag. Spray foam insulation does not contain significant quantities of recycled content.

Are reusable at end of life – which is not possible with chemical-based products, like spray foam.

Don’t give off potent greenhouse gasses – which isn’t true of many spray foam insulation products.

Our focus is on meeting your individual requirements for the widest variety of applications.

Construction Contractors has a proven track record of successfully completing many large scale retail projects. We do whatever it takes to satisfy our clients. Our long-term relationships with numerous national clients prove our successful communication abilities and high-quality services. We exceed our clients’ expectations whether we are retrofitting an existing structure or building an entirely new store.

Construction Contractor has extensive experience working with a wide range of retailers. We have completed store build-outs for many major chains, and have big box retail construction down to a science. Our client list includes both national and international companies. At the same time, we treat each client like our most important client, because they are.

Many companies base their bids on the lowest possible subcontractor and supplier cost. This can result in less-than-timely and quality work. We take a different approach. We’ve developed a crew of trusted superintendents, and a consistent core of subcontractors, that maintain top-notch standards of production and efficiency. Quality matters to us more than anything else.

Like all companies, We welcome new business. We are always working to expand our client base. However, the vast majority of our clients are repeat customers, many of whom have been using our services for years. They know they can count on us to get things done right.

We are dedicated not only to making the construction process enjoyable and beneficial, but to ensuring safe and injury free working environments for our associates, subcontractors and clients. We view risk management and the health and safety of each associate and subcontractor as the most important and vital to our operations.

Life is all about balance. Being a leader in the design-build construction industry is hard work, but we make sure it’s also a lot of fun. Whether it’s getting together to have fun with the team or giving back to the community through a variety of philanthropic organizations, or just playing a round of office Ping-Pong, we believe part of supporting each other is spending quality time together.

We can make it happen. We offer free consultation to achieve your goals with creativity and quality that you deserve.